Stock & Noble

The 5 biggest problems to avoid during your horse fencing project.

- BY Tripti Kakkar

When you start building your property, fencing is an integral part of your project. While you plan and prepare for everything to go as smoothly as possible, sometimes some issues are beyond your control. These problems could delay your project, and lead to disappointment and wastage of resources, time and effort.

At Stock & Noble, we have years of experience in providing the finest fencing solutions to our clients across Australia and New Zealand. We’ve managed several fencing projects from start to finish. We know the major pitfalls that you might face in the process of executing your fencing project and are also aware of a way out of them, to avoid them or be prepared for them.

In this article, we will discuss the 5 biggest problems that can happen during your fencing project. We will also discuss their solutions which will help you plan better and stay prepared so there’s less disappointment, more acceptance and hopefully success.

Problem#1: Hitting rock bottom

Problem #2: Running out of fencing material

Problem #3: Actual fencing not matching your marking

Problem #4: Availability issues with your Fencing Contractor

Problem #5: Not able to adjust to the weather

At the end of this article, you will be aware of the biggest problems that can happen in your journey of getting the most beautiful fencing for your property and learn how to handle them more wisely and calmly.

Problem#1: Hitting rock bottom

As you look at a piece of land, you would never know what surprises it has hidden beneath the surface. One of the biggest surprises is rock. Not a pleasant one though. You get to know this either after the inspection is done by the Fencing Contractor or as you start digging for the installation of the post. If you have chosen a post and rail fence for your property, rock could cause problems when installing posts in the ground.

Solution: Change the spacing of posts or drill through the rock

If you find rock under the installation site, don’t start panicking. It does happen during fencing projects. But be prepared to factor in more time and money to install your posts. You need to find a way around or through the rock.

So, if you are installing Horserail, consider changing the spacing of your fence posts. However, this might only be a temporary fix as the next hole could have rock again.

If you’re putting in Timber or Steel Post and Rail like Buckley Steel Fencing System, the post spacing is critical so you might have to get a rock cutting augur or add rock cutting teeth attachment to your existing equipment and drill through the rock.

We also recommend checking Fencing Contractors’ quotes before you begin your project. They usually have a condition related to hitting rock mentioned in the fine print. Take note of the amount so that if the situation does arise you are fully aware of the additional cost.

Problem#2: Running out of fencing material

Sometimes fencing supplies come in a standard length, say 200-meter role for EquiRope. However, you might have a 230-meter fence or if your fence is planned on paper, at times the measurements tend to differ when you actually start to install. It’s not uncommon to run out of fencing supplies. However, it becomes a big issue if you’ve ordered much sought-after fencing with a limited supply and the supplier has no prior information on your additional requirement.

Your project might get delayed simply because you have had to wait for the stock or pay extra for the delivery of a few materials. We want to help you prevent this from happening.

Solution: Check stock and place an extra order during the initial purchase

This problem can simply be solved by ordering 10% extra fencing material at the beginning of your fencing project. It helps in accommodating any errors in fence planning and also avoids any delays in the project due to a lack of supplies.

This extra material can also be used for easy and quick replacement jobs that happen in the future.

Also, while ordering your fence, find out beforehand about the availability of extra stock and lead times of your chosen fencing. You should keep your fencing supplier in the loop at the start and also during the installation of your project. If there’s any requirement it can be met on time.

Problem#3: Your actual fencing not matching your marking

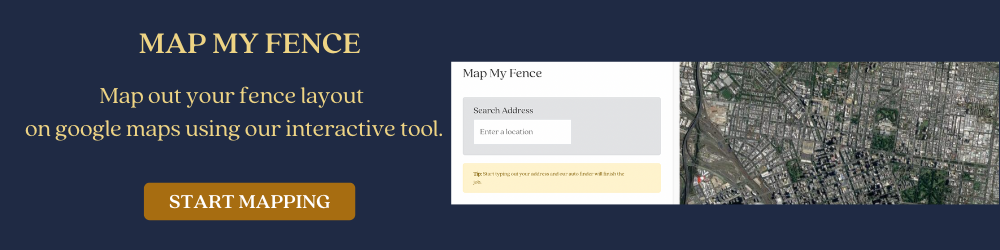

It happens in almost 60% of the projects. As you plan your fence using online mapping tools or paper, you tend to draw perfectly straight lines. Interactive mapping tools give you a great start. However, the problem is when you start the fencing project, there’s undulation, which means uneven land that goes up and down as well as obstacles like trees or power poles that need to be tackled.

This creates an unforeseen and unexpected delay in your project. To get the right fencing at right time, it is extremely important to plan right.

Solution: Physically map out your measurements on the ground

The way to solve this is to use a mapping tool to guide you, but once that’s done, always check the measurements on the actual ground. Step it out and mark your lines to order the right amount of fencing materials. If you don’t know how to go about it, you can always take help and guidance from your Fencing Contractor to measure the exact meterage.

Problem#4: Availability issues with your Fencing Contractor

Good Fencing Contractors are one of the biggest factors in ensuring your fencing is installed perfectly, on time and as you’ve imagined. Every region has its own set of experts.

The problem is there is a huge demand for good Fencing Contractors, and they are always tied up with different projects. This may be due to multiple situations like weather or the time of the day that allows work. There are fewer hours of daylight in the winter months and in the summers there are several projects lined up for them.

Solution: Check for references and over-communicate with your fencing supplier and contractor.

The solution is to have a constant channel of communication with your fencing supplier as well as the contractor. It’s a good idea to check with your fencing supplier to help you connect with a few reliable Fencing Contractors around your location.

Do your due diligence and find out about other projects your preferred Fencing Contractor has done in the past. Ask them for references and check out the properties yourself.

Keep an eye on your fencing material and lead times. We would advise even if your Fencing Contractor were available for say 2 months, order your fencing material and have it delivered on time. In case any other projects get delayed or cancelled they can start your project, without a lack of materials standing in the way

As an option, you can also choose to install your fencing yourself.

Problem#5: Inability to adjust to the weather

Every region and area comes with its own weather challenges. Heavy rains that result in floods have derailed many projects in the past. In the case of a simple drizzle, installation isn’t a problem. However, if the ground becomes too wet and it is impossible to install fencing, you’ll have to wait until the ground dries off, which can sometimes take up to four weeks. Your project could be pushed back costing you extra time as well as money.

Not just the rain, but even the sun can play its part in affecting your project adversely. If the harsh sun makes the ground rock hard, digging holes and installation of posts can prove to be extremely challenging. You also need to be mindful of the fire danger that presents itself in the summer months, especially while welding.

Solution: Accept and learn to deal with the elements

This is one of the problems which you cannot do much to solve. The best is to prepare and plan for installation around spring if possible. Even then if the weather doesn’t play along and your Fencing Contractors can’t get onsite or ask for more time you know that it’s fair. And fairly common.

Are you ready to face the installation challenges and ensure your fencing project is a success?

You wanted to start your fencing project and learn about problems that could arise and delay your dream. Now you know the 5 biggest problems that could happen when you start your installation and how to get ahead of them.

You are more knowledgeable about the pitfalls, and more prepared on how to deal with them without getting disappointed and losing the drive to achieve your vision.

In some cases, these problems can be dealt with by more planning, extra ordering, investing more time and money, marking out fences physically and constant communication with your supplier and contractor. However, when you deal with natural elements there’s not much you can do other than wait for the better days and keep your spirits high.

For a successful fencing project, it’s good to be prepared for the problems, and also important to plan the next steps once you’ve ordered your horse fencing. Together this knowledge will help you make the best decisions.

If you have more questions about the availability of stock, lead times, planning for your fence or choosing the perfect solution for your property, book a free consultation. One of our fencing advisors will reach out and listen patiently to what you and your property need to help turn your vision into a reality.